Quality

The most important thing for us is the quality of our products

Technology supported by material

S-tines is designed to work in the toughest conditions are made of the highest quality flat steel rolled in Convex profile. This protects the flat bar against loss of mechanical strength during hot forming. This in turn makes the tine better protected against breakage and can work in the field with much greater intensity.

Bars rounded corners are lowering risk of surface cracks creation during shaping – it increases tines lifetime

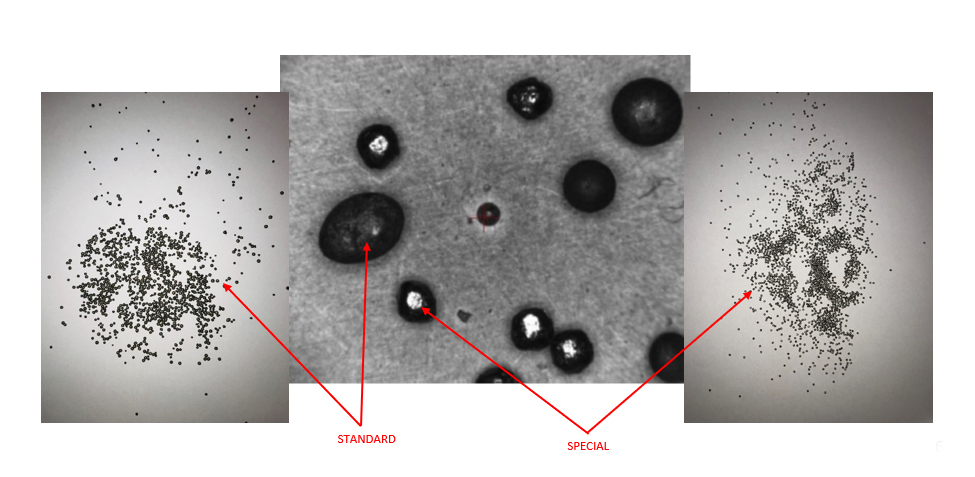

Surface treatment “shot peening”

All S-tines go through shot blasting station. Most of small surface cracks they could appear during forming / shaping is closed within that process what again increases tines lifetime

Andersen Steel has patented additional shot blasting process to remove completely small surface cracks and to increase lifetime of tines even more. It is second shot blasting step done with special short blasting instead of standard one

Technology is our advantage

During the production process after hot forming and before painting, all tines are loaded with maximum force, which allows them to keep their shape for years of use

Guarantee of quality

Quality control system allows us to maintain the highest standards of quality and our business partners to provide products that meet all requirements.

Tines made of Convex profile flat bars:

- they always work in the soil at the same depth,

- can work in more difficult conditions,

- keep their shape for years

- they retain their functionality much longer than those made of standard flat bars